Testing

Achieving the highest standards in terms of quality and safety has always been a prime focus for us.

Our range of standard components have all been tested to exacting criteria, with full supporting test documentation available. We can also arrange for appropriate testing of bespoke manufactured products.

There is a dedicated test facility at IAM Design which is used to ensure that the systems and components meet the required functional and performance standards required. The tests are conducted by qualified experts before, during and after production to ensure comprehensive analysis is achieved. The resulting data is then fed into ongoing research and development to further enhance the performance of our handrail systems.

This in-house testing is also backed by third party certification whereby the products are submitted to independent test houses to ensure conformance with the appropriate standards including BS 6180 and BS 6399-1.

Testing procedures are designed to cover a range of functional and performance criteria including:

|

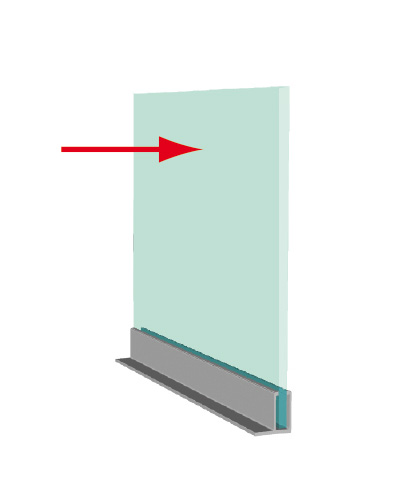

Horizontal Pressure ResistanceThis test examines the mechanical resistance to loads in railings, balustrades and balconies. Break loads are calculated by applying horizontal thrust forces up to the handrail for a defined time period. |

|

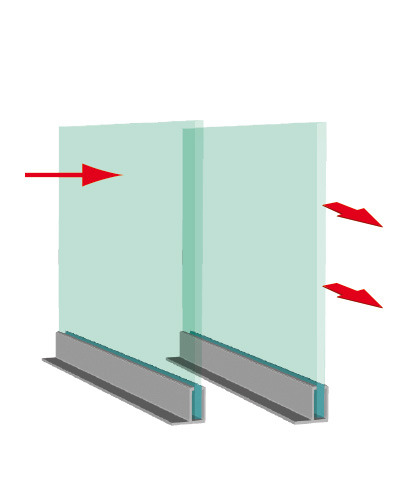

Traction ResistanceThis test is designed to calculate the mechanical resistance to loads in ready-made railings, balustrades and balconies, establishing the size, features and mechanical performance depending on their final use and location. |

|

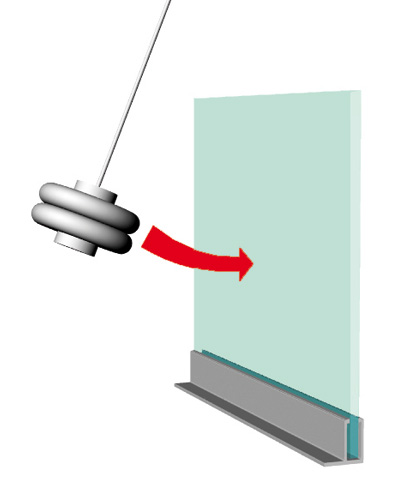

Impact ResistanceThis test requires a moving body to crash into the most critical point on a piece of glass held in position by Glass U profiles. The 1.5 metre long pendulum passes through 30 degrees from the point of release to impact. |

|

Corrosion ResistanceThis test measures the effects of neuter salt mist (NSS), acetic acid salt mist (AASS) and cupro acetic salt mist (CASS) on metal products. It evaluates their corrosion resistance, with and without anti-corrosion protection. The items under test are placed in a room in which a 5% NaC1 saline solution is emitted with a Ph from 6.5 and 7.2 and at a fixed temperature of 35°C for a duration of 120 hours. |